How to Prepare your Diesel Engine for Winter

Sep 15, 2022

The first official day of winter might be a few weeks away but if you own or operate a truck with a diesel engine, it is time to start gearing up for the change in weather, and there is more to winterizing than tires and chains.

Diesel engines behave differently in cold weather than their gasoline counterparts and require different maintenance to perform optimally when the temperature drops. In colder conditions, it is

more difficult for combustion to occur since diesels use super-heated air to create this reaction.

Cold conditions and changing temperatures impact how engines and their components start and

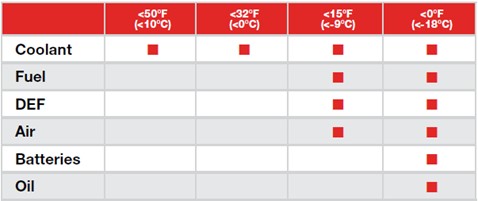

perform. Planning and preparing for these conditions properly ensure your engine is reliable and up to par—no matter what the forecast has in store. The below chart shows the engine systems affected by Temperature.

We have prepared some simple tips and product offerings that can make winter preparation of your vehicle a little less frigid.

1. To ensure combustion still happens diesel engines may have a glow plug—an additional piece added to the cylinder head—to help warm the air, or a grid heater. Checking these pieces ahead of a cold snap is important as both glow plugs and grid heaters can fail. Fortunately, they can be replaced at a low cost to keep your engine running through the winter. Engines not only need to be warm enough to run, they need to maintain their operating temperature to perform optimally. If you’re running a diesel in some seriously cold weather—below 5°F (-15°C)—you will want to make sure you have a block heater ready and that it’s working optimally.

2. While a block heater warms the engine block, a coolant heater is another option for diesel owners and operators. With a coolant heater, like one from Webasto Heaters, the focus is on specifically keeping coolant the right temperature and in doing so, reduces filter overloading, thermal cracking, maintenance costs, and it can even reduce fuel costs.

3. Coolant itself is the first line of defence for your engine in cold weather. Choosing a coolant and coolant system protection can save your engine from a range of problems like corrosion, acidification, and scale and deposits. Fleetguard coolants offer the best in freeze and boil over protection and meet all kinds of needs for all kinds of engines—including diesel.

4. Dropping temperatures also mean it’s a good time to double check your battery. Heaters and other winterizing features and modifications can require a lot of current. If your battery is in questionable condition, you’ll want to look at a replacement to avoid a potential onslaught of problems. Cummins batteries are a maintenance-free choice with a stamped fully framed grip, a leak-free bond to eliminate terminal corrosion, and up to 10% more acid above the plates to yield a longer life.

5. Fluids in your engine can behave differently in cold conditions. Diesel fuel can become cloudy and “gel up” where the consistency changes, becoming too thick, and plugging fuel lines, filters, pumps, and injectors. Power Service Diesel additives Prevent Fuel Gelling and Protects Against Fuel-Filter Icing and also provide options to reliquefy gelled fuel and de-ice frozen fuel filters

6. Ensure fuel fluidity with a thermostatic radiator valve (TRV) and fuel warmer separator filters. You’ll also want to ensure you keep your oil warm as a dip in temperature can increase oil viscosity making it thicker and causing more friction and early engine wear. Both an oil heater and oil pan cover can work to keep oil the right consistency to move smoothly and ultimately require less consumption.